Artificial leather, often celebrated for its versatility and ethical appeal, has become a popular alternative to traditional leather in various industries, including fashion, automotive, and upholstery. The production of artificial leather base fabric is a sophisticated process that combines technology and creativity, resulting in a durable and aesthetically pleasing material. Here’s a closer look at the key processes involved in its manufacturing.

Material Selection

The journey begins with the selection of core materials. The base fabric for artificial leather is typically made from synthetic fibers like polyester or nylon, chosen for their strength and durability. These materials serve as the backbone of the artificial leather, providing structural integrity. The outer layer is generally composed of either polyurethane (PU) or polyvinyl chloride (PVC), both of which are designed to replicate the look and feel of natural leather.

Fabric Coating

Once the materials are prepared, the next step is the coating process. This involves applying a layer of synthetic material onto the base fabric. Several techniques can be employed for this purpose:

Knife Coating: A blade is used to spread a uniform layer of the coating material over the fabric, ensuring consistency in thickness.

Rotary Screen Printing: This method uses screens to print the synthetic material onto the fabric, allowing for intricate patterns and textures to be created.

The coating process is crucial, as it determines the initial properties of the artificial leather, such as texture and durability.

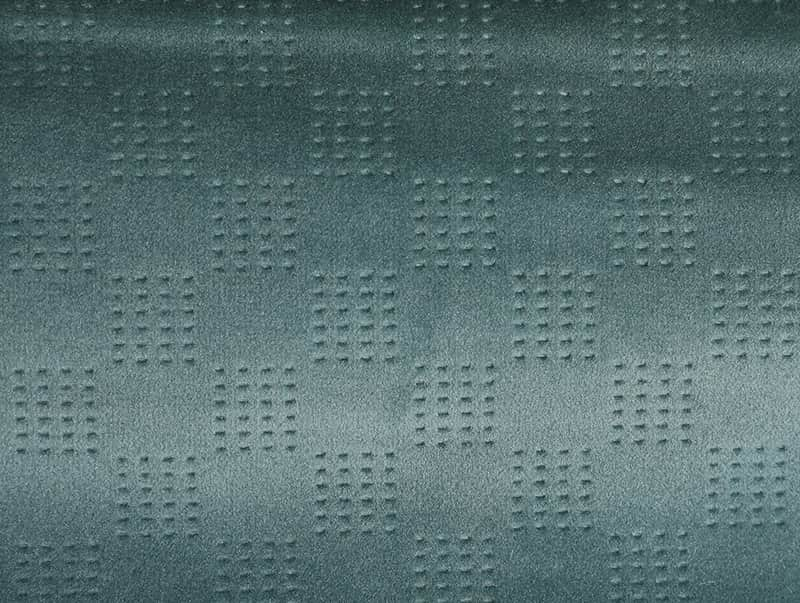

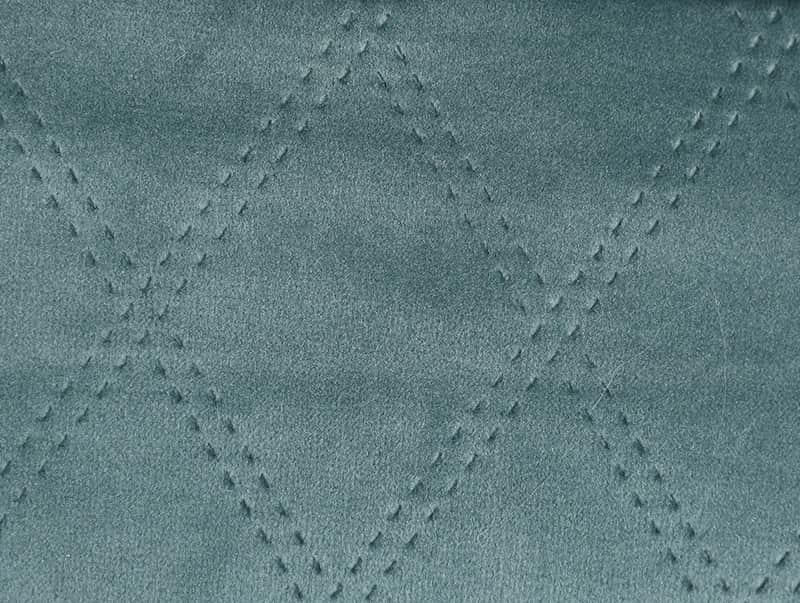

Embossing

To achieve the desired look, the coated fabric often undergoes embossing. This process involves passing the fabric through heated rollers that imprint textures mimicking the natural grain of leather. The result is a visually appealing surface that enhances the material's authenticity. Embossing not only contributes to the aesthetic but also helps in creating a tactile experience that consumers expect from leather-like products.

Curing and Drying

After embossing, the fabric is subjected to a curing process. This involves applying heat to bond the synthetic material securely to the base fabric. Curing also helps to evaporate any solvents that may have been used during the coating, ensuring that the final product is not only durable but also safe for use. This step is vital for enhancing the material's overall resilience and longevity.

Finishing Touches

The finishing process includes additional surface treatments that can enhance specific properties of the artificial leather. Manufacturers may apply coatings to improve water resistance, UV stability, or scratch resistance. These treatments add value to the product, making it suitable for a wider range of applications and environments.

Cutting and Quality Control

Once the artificial leather base fabric is fully processed, it is cut to size according to various application requirements. Quality control checks are then performed to ensure that the material meets industry standards for consistency in texture, color, and performance. This final inspection is crucial, as it guarantees that consumers receive a high-quality product.

Embracing Sustainability

In response to increasing environmental concerns, many manufacturers are adopting sustainable practices in the production of artificial leather. This includes using recycled materials, low-impact dyes, and eco-friendly production methods. As consumer preferences shift toward more sustainable options, these innovations are helping to reduce the ecological footprint of artificial leather production.

The manufacturing of artificial leather base fabric is a multi-step process that intricately combines material science and craftsmanship. From material selection to final finishing, each stage plays a critical role in creating a product that not only serves as a viable alternative to natural leather but also meets the evolving demands of consumers for quality, aesthetics, and sustainability. As technology advances, the future of artificial leather looks promising, with continued innovations likely to enhance its performance and reduce its environmental impact.