To enhance the sheen and softness of curtain velvet fabrics, several finishes and treatments can be applied. Each treatment has its own unique effect on the fabric, contributing to its aesthetic appeal and tactile qualities. Here are some common finishes and treatments used:

Shearing:To achieve a uniform pile height and smooth surface.Velvet is passed through shearing machines that trim the pile to an even length, enhancing its sheen and softness.Produces a more lustrous surface and softer hand feel by eliminating uneven fibers.

Brushing: To soften the pile and enhance the fabric's sheen.The velvet fabric is brushed gently to lift and align the fibers.Results in a softer texture and a shinier appearance due to the alignment of the pile.

Heat Setting: To stabilize the fabric and improve its luster.The velvet is exposed to controlled heat, which sets the pile and enhances its sheen.Enhances the fabric’s durability and provides a glossy finish by locking the fibers in place.

Chemical Finishing:To enhance softness, sheen, and overall hand feel. The velvet is treated with chemicals like silicone, softeners, or gloss finishers.Produces a softer, more luxurious feel and a shiny surface by coating the fibers.

Calendaring: To smooth the fabric and enhance its sheen.The velvet is passed between heated rollers under pressure.Results in a sleek, shiny surface by compressing and polishing the fibers.

Singeing: To remove surface fuzz and achieve a cleaner appearance.The fabric is quickly passed over a flame or heated surface to burn off loose fibers.Produces a smoother and shinier surface by eliminating unwanted fuzz.

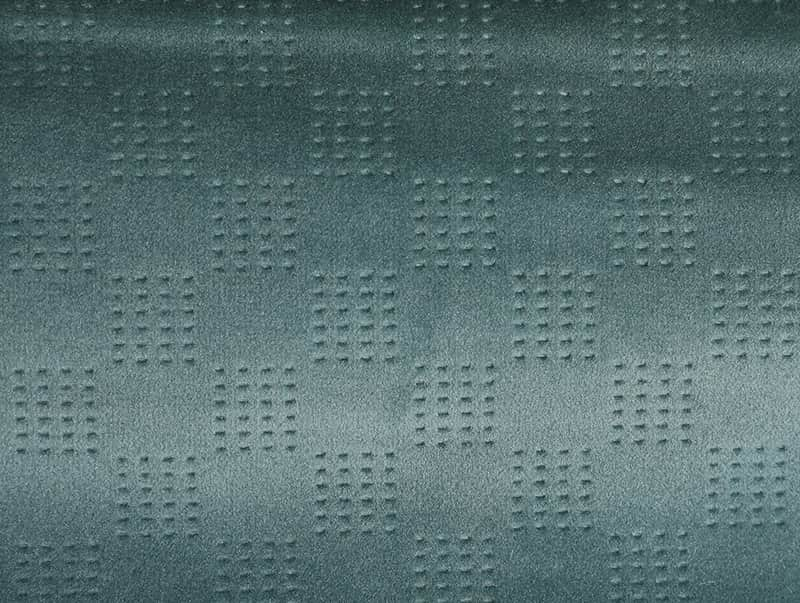

Embossing: To create decorative patterns with enhanced texture and sheen.Velvet is pressed with engraved rollers or plates to imprint designs.Adds a textured pattern that reflects light differently, increasing the fabric's sheen and giving a three-dimensional appearance.

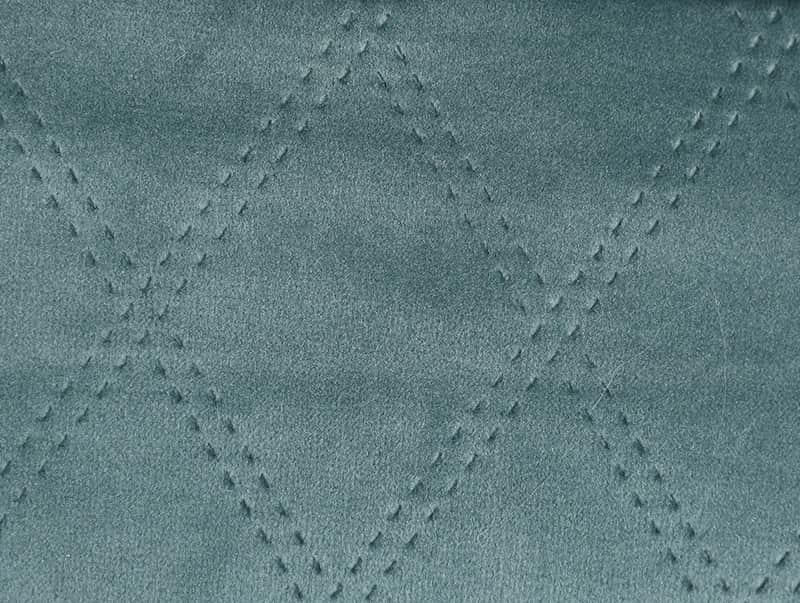

Crushing: To create a luxurious, textured appearance with varying levels of sheen.The fabric is twisted or pressed while wet to create an irregular, crushed look.Results in a unique, shiny texture that catches light at different angles.

Glazing: To impart a glossy finish to the fabric.A thin resin or wax coating is applied, followed by polishing.Produces a high-gloss surface with increased luster.

Milling: To soften the fabric and enhance its sheen.The velvet is gently agitated in water or a mild chemical solution.Loosens the fibers to increase softness and add a subtle sheen.

Siliconizing: To improve the softness and luster.The fabric is treated with silicone-based softeners.Enhances the fabric's softness and provides a silky, shiny finish.

Napping: To enhance the softness and fluffiness of the fabric.The surface is brushed to raise the fibers.Creates a softer texture and increases the perceived sheen by aligning the fibers.

Teflon Coating: To protect the fabric and maintain its sheen.The fabric is treated with a Teflon-based finish.Provides a protective layer that helps maintain the fabric's shine and makes it more resistant to stains and moisture.

Mercerizing: To increase the fabric’s sheen and dye absorption.The velvet is treated with a caustic soda solution and then neutralized.Enhances the fabric's luster and makes it more vibrant and durable.

These finishes and treatments not only enhance the visual appeal and softness of curtain velvet fabrics but also improve their overall performance and longevity. Each method can be selected and tailored based on the desired effect and specific requirements of the application.