To maintain the breathability of artificial leather base fabrics, several measures can be taken during the manufacturing process:

Selection of Materials: Artificial leather base fabrics are often crafted using synthetic fibers or blends specifically chosen for their breathable properties. These materials allow for air circulation and moisture vapor transmission, crucial for maintaining comfort and reducing heat buildup. By selecting fibers that facilitate airflow, manufacturers ensure that the fabric remains breathable even when coated or treated for additional functionalities such as water resistance.

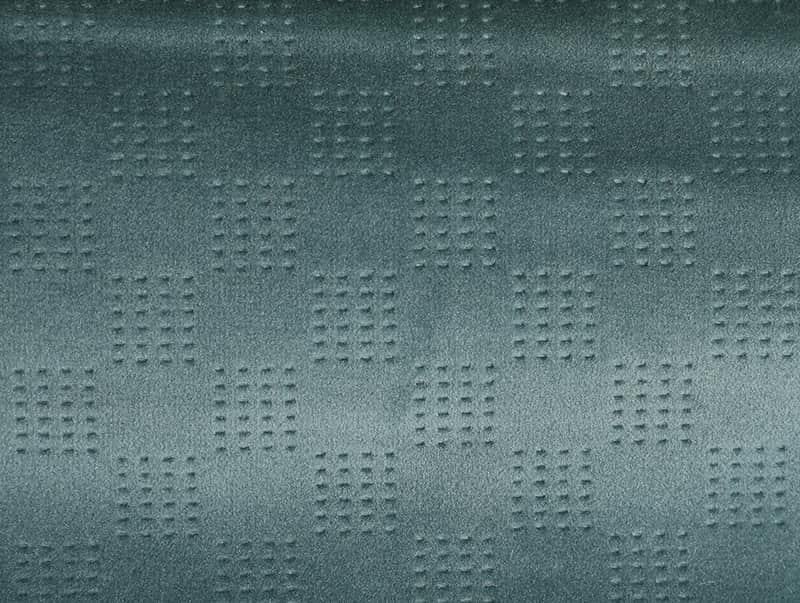

Perforation or Micro-perforation: During the manufacturing process, artificial leather base fabrics can be perforated with small holes or micro-perforations. These perforations enhance airflow through the fabric, improving its breathability without compromising its structural integrity. By strategically placing these perforations, manufacturers can tailor the fabric's ventilation capabilities to suit different applications, ensuring optimal comfort in various environmental conditions.

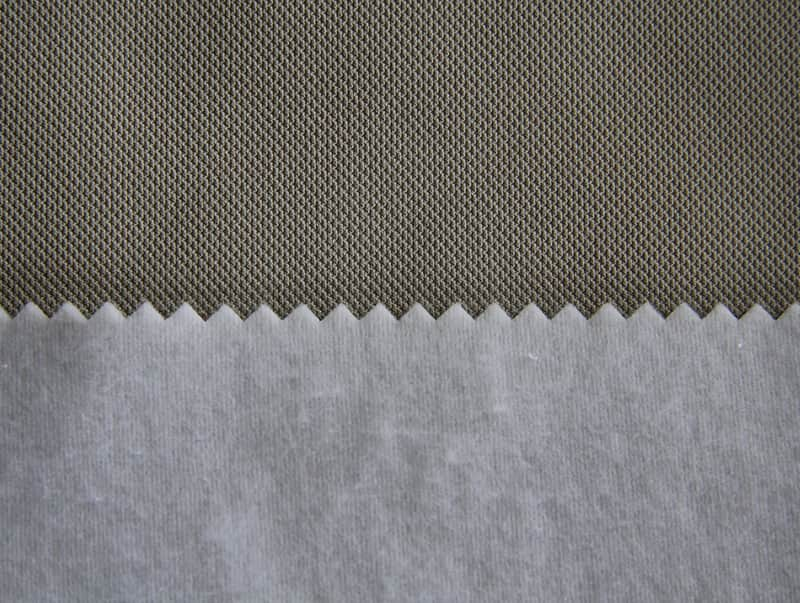

Textile Structure: The textile structure of artificial leather base fabrics plays a crucial role in their breathability. Manufacturers may employ weaving or knitting techniques that promote air permeability. For instance, using open weaves or knits allows for better ventilation, ensuring that the fabric remains breathable. By optimizing the textile structure, manufacturers enhance the fabric's ability to regulate temperature and moisture, thereby enhancing comfort for users.

Breathable Coatings: Some artificial leather base fabrics are treated with breathable coatings or finishes. These coatings are designed to maintain the fabric's ability to "breathe" while providing additional functionalities such as water resistance or stain resistance. Breathable coatings allow moisture vapor to escape from the fabric while preventing liquid penetration, ensuring that the fabric remains comfortable and functional in various weather conditions.

Moisture Wicking Properties: To enhance breathability, artificial leather base fabrics may incorporate moisture-wicking treatments or yarns. These treatments help draw moisture away from the skin and facilitate its evaporation, thereby preventing the buildup of sweat and maintaining a dry and comfortable environment. By incorporating moisture-wicking properties, manufacturers ensure that the fabric remains breathable and suitable for prolonged use in active or humid conditions.

Testing and Validation: Manufacturers conduct rigorous testing to validate the breathability of artificial leather base fabrics. This includes airflow and moisture vapor transmission tests to assess how effectively the fabric allows air and moisture to pass through. By testing the fabric against industry standards and performance criteria, manufacturers ensure that it meets specified breathability requirements for different applications. Testing and validation procedures also help identify areas for improvement, allowing manufacturers to continually enhance the breathability of artificial leather base fabrics.

These measures collectively ensure that artificial leather base fabrics maintain optimal breathability, providing comfort and performance in various applications ranging from upholstery and automotive interiors to apparel and footwear.